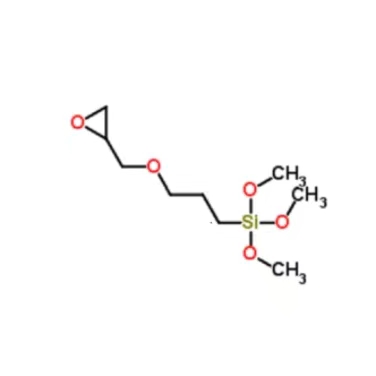

3-Glycidoxypropyltrimethoxysilane

Product details

1.This product is widely used in ship coatings, metal coatings, automotive coatings, and industrial anti-corrosion coatings to increase the adhesion and anti-corrosion properties of coatings.

2.This product can improve the adhesion of epoxy resin and substrate, improve the electrical properties of epoxy resin electronic materials, potting materials, printed circuit boards, especially the the wet electrical properties.

3.Mainly used in unsaturated polyester composite materials, it can improve the mechanical properties, electrical properties, light transmission properties of composite materials, especially can greatly improve the wet performance of composite materials.

4.Impregnating glass fiber (containing this coupling agent) can improve the wet mechanical strength and electrical properties of glass fiber reinforced composite materials.

5.In wire and cable industry,the coupling agent is used to treat the EPDM system filled with clay peroxide cross-linked , improving the consumption factor and specific inductance and capacitance.

6. Copolymerized with vinyl acetate and acrylic acid or methacrylic acid monomers, these polymers are widely used in coatings, adhesives and sealants to provide excellent adhesion and durability.

Product physical indicators

| CAS NO | 2530-83-8 |

| Density at 25℃ | 1.07g/ml |

| Boiling Point | 290℃ |

| Refractive Index(25℃) | 1.428 |

| Flash Point | 110℃ |

| Purity | ≥97% |

| Appearance | Colorless transparent liquid. |

| Solubility | Soluble in alcohol, easily hydrolyzed. |

Use and effect

KH-560 is an essential ingredient in the products of many industries.Such as:

1.Glass fiber/glass fabric composites: as a finish or a size ingredient.

2.Foundry resins: as an additive to polyurethane resins.

3.Sealants and adhesives: as a primer or additive.

4.Mineral filled composite: for pretreat- ment of fillers and pigments or as an additive to the polymer.

5.Paints and coatings: as an additive and as a primer for improving adhesion to the substrate, especially glass and metal.

6.Improved shelf life over aminosilanes in polyurethanes

The KH-560 brings important performance to the end product, including:

1.Improved mechanical properties, such as flexural strength, tensile strength, impact strength and modulus of elasticity.

2.lmproved moisture and corrosion resistance.

3.Improved electrical properties, such as dielectric constant, volume resistivity.

KH-560 can also improve such processing properties as:

1.Increased filler dispersion

2.Rheological behavior (i.e.viscosity reduction)and Newtonian behavior.

3.Increased filler loading.

4.None yellowing.

Storage

Sealed, cool room temperature, dry and ventilated, away from fire and heat sources.